In elemental analysis, measurement accuracy and uncertainty are fundamental requirements in ensuring reliable data for scientific interpretation of results, and subsequent decisions stemming from those results. So whether a lab tests environmental samples, pharmaceuticals, or industrial materials, the accuracy of its analytical results depends on the quality of reference materials it uses – as evidenced by the uncertainty and traceability information that accompanies them. In this article, we discuss how LGC Standards’ rigorous approach to traceability and uncertainty – using a robust and accurate HP ICP-OES method developed by NIST – means that you can rely on our Certified Reference Materials (CRMs).

Introduction

In the hierarchy of reference materials, Certified Reference Materials (CRMs) represent an extremely high level of reliability and traceability. ISO 17034 defines a CRM as a “reference material characterized by a metrologically valid procedure for one or more specified properties, accompanied by a reference material certificate that provides the value of the specified property, its associated uncertainty, and a statement of metrological traceability.” CRM manufacturers have a responsibility to utilise the best methods for certification of their products. This includes not just the accurate certification of concentration, but also the presentation of a meaningful uncertainty term for that stated concentration, in addition to trace element data for defining the purity of the standard.

LGC Standards employs a High Performance Inductively Coupled Plasma–Optical Emission Spectrometry (HP ICP-OES) method developed by NIST to certify our single element CRMs. This method is characterised by exceptional accuracy, precision, and robustness, making it well suited for the certification of high-purity single element solution standards.

What is HP ICP-OES?

HP ICP-OES is an enhanced version of traditional Inductively Coupled Plasma–Optical Emission Spectrometry (ICP-OES), a technique that uses plasma to excite atoms in a sample and measures the intensity of light they emit at characteristic wavelengths. While traditional ICP-OES is already a robust method for multi-element detection, High Performance ICP-OES leverages the advantages of array-detector based instruments to carry out:

simultaneous analyte and internal standard measurement, and

time-synchronised offline background correction.

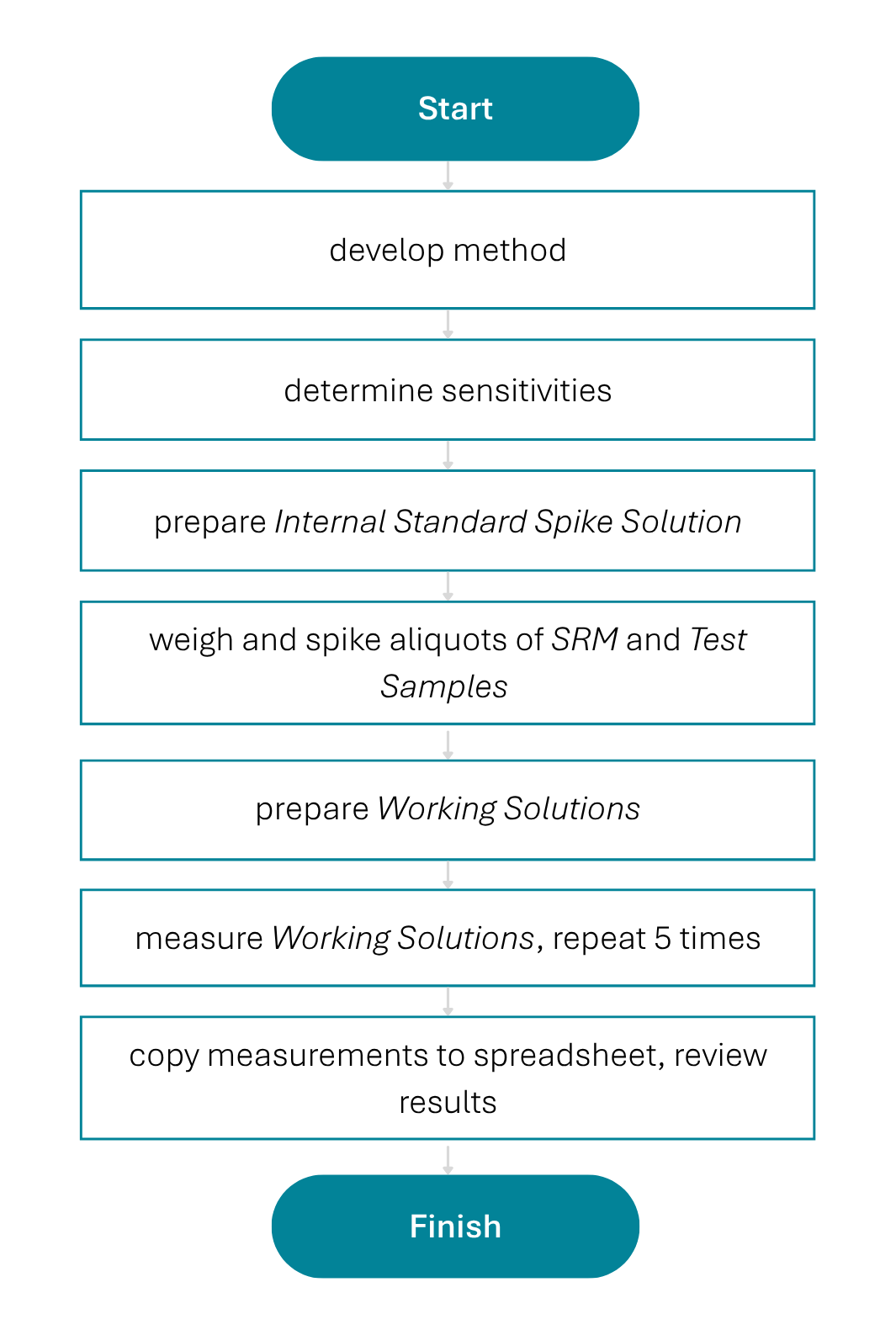

The HP ICP-OES protocol developed by NIST includes two components: (a) an analytical procedure for sample preparation and measurement, shown in Figure 1, and (b) a data processing tool in Excel® for calculating concentrations traceable to NIST Standard Reference Materials (SRMs). It is designed to provide an accurate measurement, as well as a statistically meaningful, traceable uncertainty value.

Figure 1. Diagram of the NIST HP ICP-OES Method, adapted from Turk and Salit, 2005.

The method achieves relative expanded uncertainties in the order of 0.1%, making it suitable for high-precision applications such as the certification of CRMs.

Case Study - analysis of single element standards using NIST guidelines

Over a four month period, the LGC Standards laboratory in Manchester, NH conducted an extensive analysis of various single element standards using the NIST HP ICP-OES protocol. This rigorous approach enabled the precise determination of certified concentrations, with the results shown in Table 1 (below).

Table 1. Certified Concentrations of Single Element Standards Using HP-ICP-OES

| Element | Expected Concentration (mg/L) | Determined Concentration using HP ICP-OES (mg/g) | Standard Deviation | Relative Standard Deviation (%RSD) |

|---|---|---|---|---|

Na | 40,000 | 39.8446 | 0.0955 | 0.240 |

Ag | 10,000 | 9.9496 | 0.0285 | 0.302 |

Ho | 10,000 | 9.6621 | 0.0306 | 0.317 |

Mn | 10,000 | 9.5466 | 0.0287 | 0.301 |

Ni | 10,000 | 9.5623 | 0.0288 | 0.301 |

P | 10,000 | 9.4369 | 0.0380 | 0.403 |

U | 10,000 | 9.5007 | 0.0297 | 0.313 |

As | 1,000 | 0.9947 | 0.0037 | 0.372 |

Au | 1,000 | 0.9645 | 0.0026 | 0.270 |

Co | 1,000 | 0.9739 | 0.0030 | 0.308 |

Eu | 1,000 | 0.9797 | 0.0035 | 0.357 |

Ni | 1,000 | 0.9747 | 0.0030 | 0.308 |

Pb | 1,000 | 0.9952 | 0.0031 | 0.311 |

Sr | 1,000 | 0.9809 | 0.0035 | 0.357 |

V | 1,000 | 0.9700 | 0.0040 | 0.412 |

The method demonstrated an average precision of 0.326%, which is considered excellent for spectrometric techniques. This value reflects the total traceable uncertainty, incorporating all contributing sources, including the NIST Standard Reference Material (SRM). While traditional methods such as gravimetric and titrimetric analysis typically achieve precision around ±0.3% Relative Standard Deviation (RSD) for single element standards, the HP ICP-OES method delivers comparable precision, validating its suitability for high-accuracy applications.

LGC Standards – accuracy and traceability you can trust

LGC Standards employs the NIST High Performance ICP-OES methodology to certify its single element CRMs. This advanced technique ensures that the certified concentrations listed on the Certificate of Analysis (CoA) are directly traceable to NIST SRMs, providing a high level of confidence in both accuracy and traceability.

By using this method, LGC Standards delivers CRMs that meet the rigorous demands of modern analytical laboratories - supporting regulatory compliance, method validation, and data integrity. Whether you're working in pharmaceuticals, environmental testing, food and beverage, or industrial quality control, you can rely on LGC Standards CRMs for consistent, traceable, and scientifically defensible results.

|